Views: 0 Author: Site Editor Publish Time: 2026-01-09 Origin: Site

You face many choices when selecting a flat rubber gasket for your system. Each gasket material and type offers unique strengths. Temperature resistance matters if your equipment operates in extreme conditions. Chemical compatibility ensures safety when handling aggressive substances. Durability extends the life of your gaskets, while cost affects your overall budget. Soft gaskets hold over 32% of the market because they provide versatility and cost-effectiveness across industries. If you want effective sealing and reliable performance, trust brands like Lixu Rubber to meet your needs with quality options in all types of gaskets.

When you choose a flat rubber gasket, you need to understand the different gasket materials available. Lixu Rubber offers a wide selection of gasket materials, each designed for specific uses and environments. Advances in material science have led to new high-performance and eco-friendly flat gaskets, giving you more options for your sealing needs.

NBR gaskets stand out for their excellent oil resistance. You often see these gaskets in automotive and industrial settings where petroleum and grease are present. The material provides a reliable seal and helps prevent leaks in engines and machinery.

EPDM gaskets resist UV rays, ozone, and weather. You can use these gaskets outdoors or in HVAC systems. The material keeps its shape and performance even after long exposure to sunlight and harsh conditions.

Silicone gaskets offer high temperature tolerance and meet FDA standards. You find these gaskets in food processing, medical devices, and high-temperature equipment. The material stays flexible and safe for sensitive applications.

FKM gaskets deliver outstanding chemical and fuel resistance. You rely on these gaskets in demanding environments like petrochemical plants and aerospace systems. The material maintains its sealing ability under extreme conditions.

Neoprene gaskets provide versatility and weather resistance. You can use these gaskets in marine environments and outdoor equipment. The material protects against water, ozone, and moderate chemicals.

Butyl gaskets are known for chemical resistance and gas impermeability. You use these gaskets in industrial applications where you need to block gases and chemicals. The material helps maintain a tight seal over time.

You may need sponge gaskets for cushioning and vibration reduction. Specialty materials like cork and paper offer unique properties for specific uses. These materials help you solve sealing challenges in custom applications.

Recycling rubber gaskets helps reduce waste and conserves resources. You support environmental health by choosing recyclable gasket materials when possible.

Material science continues to improve gasket materials, giving you better longevity, thermal resistance, and compliance with industry standards. You can trust Lixu Rubber to provide flat rubber gasket solutions that meet your needs.

You need to consider temperature resistance when selecting a flat rubber gasket. Each material responds differently to heat and cold. High temperatures can cause some gaskets to lose flexibility or break down. Cold temperatures may make rubber stiff and brittle, leading to cracks and leaks. Silicone gaskets perform well in extreme cold and retain elasticity, making them ideal for environments with wide temperature swings. Nitrile gaskets offer cost-effective solutions but may shrink in low temperatures.

Here is a table showing the temperature ranges for common gasket materials:

Material | Temperature Range |

|---|---|

NBR | -30°F to +220°F |

EPDM | -40°F to +300°F |

Silicone | -80°F to +450°F |

FKM | -20°F to +400°F |

Neoprene | -40°F to +200°F |

Butyl | -40°F to +225°F |

Sponge | N/A |

Silicone gaskets maintain flexibility and sealing properties from -80°F to +450°F. You can use them in automotive, food processing, and electronics. EPDM gaskets work well outdoors and in HVAC systems, handling temperatures from -40°F to +300°F. FKM gaskets resist high temperatures and chemicals, making them suitable for petrochemical and aerospace applications. Lixu Rubber offers gaskets that cover a wide temperature range, ensuring reliable sealing in both high and low-temperature environments.

Tip: Always match the temperature rating of your gasket to the operating conditions of your system. This helps prevent premature failure and ensures long-lasting sealing.

Chemical compatibility affects the lifespan and performance of your gasket. You must choose a material that resists the chemicals present in your application. EPDM gaskets resist water and fuel but degrade when exposed to oils and solvents. FKM gaskets handle acids, bases, and fuels, but certain amines can cause sensitivity. Silicone gaskets resist water and many chemicals but may break down with strong acids and bases.

Here is a table summarizing chemical resistance and failure causes:

Gasket Material | Chemical Resistance | Degradation/Failure Causes |

|---|---|---|

EPDM | Resists fuel, water | Degraded by oils and solvents |

FKM | Resists acids, bases, fuels | Sensitive to certain amines |

Silicone | Resists water, chemicals | Degraded by strong acids and bases |

Chemical exposure can lead to accelerated degradation. Harsh chemicals weaken the gasket and reduce sealing effectiveness. Temperature fluctuations and mechanical stress also impact durability. You should always check the chemical compatibility chart before choosing a gasket for your system.

Note: Proper material selection helps you avoid swelling, brittleness, and loss of elasticity. This reduces maintenance needs and extends the service life of your gasket.

Durability and wear determine how long your gasket will last under repeated use. You want a gasket that resists abrasion, UV light, ozone, and environmental aging. EPDM gaskets offer high resistance to weathering and abrasion. Silicone gaskets provide excellent flexibility and thermal stability. FKM gaskets deliver high tensile strength and low compression set, making them suitable for high pressures and demanding environments.

Here is a table comparing durability characteristics:

Material | Key Characteristics | Applications |

|---|---|---|

NBR | Good compression retention, moderate temperature resistance | General sealing applications |

FKM | High thermal and chemical resistance, high tensile strength | Aerospace, chemical reactors |

Silicone | Excellent flexibility, non-toxic, thermal stability | Food-grade, medical, electronics |

EPDM | Weathering, ozone, abrasion resistance | HVAC, potable water fittings |

Neoprene | Balanced chemical/weather resistance, flame resistance | HVAC, refrigeration, industrial |

Butyl | Low gas permeability, environmental aging resistance | Vacuum chambers, gas handling |

Environmental factors like UV exposure and ozone can impact gasket durability. EPDM, silicone, and FKM gaskets show high resistance to these elements. You should inspect gaskets regularly and follow recommended maintenance practices, such as cleaning surfaces and ensuring proper alignment, to extend their service life.

Cost plays a role in your gasket selection. Higher-cost materials often provide longer service life and reduced maintenance needs. Silicone and FKM gaskets may cost more upfront, but they offer extended durability and better sealing properties. Lower-cost gaskets like NBR may require more frequent replacement and maintenance.

Here is a table showing the relationship between cost and service life:

Initial Cost | Service Life | Maintenance Needs | Cost Savings Over Time |

|---|---|---|---|

Higher | Extended | Reduced | Justified |

Lower | Shorter | Increased | Not Justified |

You should balance initial cost with expected service life and maintenance requirements. Investing in high-quality gaskets from Lixu Rubber can save you money over time by reducing downtime and replacement costs.

Tip: Select a gasket that matches your application needs and budget. Quality materials help you achieve reliable sealing and lower total cost of ownership.

Choosing the right flat rubber gasket material ensures optimal sealing performance in your system. You protect your equipment, reduce maintenance, and improve reliability by matching the gasket to your operating environment.

When you select a flat rubber gasket, you need to know the main types and shapes available. Lixu Rubber manufactures flat gaskets and washers in many shapes and sizes to fit your system. You can choose from standard designs or request custom solutions for unique applications.

Full-face gaskets cover the entire surface between two flanges. You use these gaskets when you need a complete seal across the flange area. Full-face gaskets often have bolt holes that match the flange pattern. This design helps you prevent leaks and maintain a strong seal under pressure. You find full-face gaskets in water pipes, chemical systems, and industrial machinery.

Ring gaskets fit only around the sealing surface, inside the bolt circle. You use ring gaskets when you want a seal without covering the whole flange. This type works well in high-pressure systems and saves material. Ring gaskets are common in oil, gas, and steam applications. You can install them quickly and replace them easily.

You may need custom or specialty shapes for special sealing challenges. Lixu Rubber offers flat gaskets in shapes like P-seals, D-seals, E-seals, and lip seals. P-seals give you versatility for many uses. D-seals feature a half-moon bulb that seals well under pressure. E-seals work in high-temperature and chemical environments, often made from silicone or fluorosilicone. Lip seals attach with fasteners or adhesives and suit water filtration systems.

Compression molding is a cost-effective method for producing rubber gaskets with tight tolerances and strong mechanical properties. Molded gaskets offer better control over density and thickness, which leads to robust seals and longer life cycles. Precision cutting allows you to create flat gaskets in custom shapes and sizes, but die-cut gaskets may show thickness variances that affect sealing.

You can trust Lixu Rubber to use advanced compression molding and precision cutting to deliver flat rubber gasket solutions that fit your needs. These production methods help you achieve reliable seals and consistent quality in every application.

Type of Gasket | Shape/Design | Common Applications |

|---|---|---|

Full-Face | Covers entire flange | Water, chemical, industrial |

Ring | Fits sealing surface | Oil, gas, steam |

P-Seal | Versatile profile | General sealing |

D-Seal | Half-moon bulb | Pressure sealing |

E-Seal | High-temp, chemical | Chemical, high-temp environments |

Lip Seal | Edge profile | Water filtration, mechanical |

You can choose from many types of gaskets to match your system requirements. Flat gaskets come in standard and custom shapes, giving you flexibility for every project.

You need to match the right material to your application for the best sealing results. Start by looking at the chemical resistance and temperature tolerance of each flat rubber gasket. NBR works well with oil and fuel, while EPDM resists water, ozone, and sunlight. Silicone handles high temperatures and extreme cold. FKM stands up to harsh chemicals. You should also check the hardness, which affects flexibility and stability. Thicker gaskets offer better compression and sealing. Consider the operating conditions, such as pressure and media type, before making your choice.

Key factors to consider:

Material selection for chemical and temperature resistance

Hardness for sealing performance

Thickness for compression and fit

Operating conditions like pressure and media compatibility

Lixu Rubber offers a wide range of rubber gaskets designed for industrial, automotive, and household uses. You can rely on their experience to help you choose the right flat gasket for your needs.

Selecting the correct type of gasket improves sealing and system reliability. You will find several types of gaskets, including full-face, ring, and custom flat gaskets. Each type fits different flange designs and pressure ratings. The table below shows how types of gaskets perform in various scenarios:

Gasket Type | Benefits and Characteristics | Performance Considerations |

|---|---|---|

Non-metallic | Flexible, cost-effective, many shapes | Choose material for specific needs |

Semi-metallic | Combines strength and flexibility | Handles wide temperature ranges |

Metallic | High stability, tight seal | Needs precise alignment |

You should match the gasket type to your flange, media, and operating conditions. Full-face gaskets work well for complete coverage, while ring gaskets suit high-pressure systems.

Environmental factors affect gasket performance and longevity. You must consider exposure to sunlight, UV radiation, and fluctuating temperatures. Some materials, like EPDM, resist outdoor conditions. Silicone and FKM perform well at high temperatures and in harsh chemical environments. Food-grade silicone meets safety standards for food contact. Neoprene offers flexibility for moving parts.

Material Type | Key Resistance Features | Best Use Cases |

|---|---|---|

Nitrile (NBR) | Oil and fuel resistance | Automotive, machinery |

EPDM | Water, ozone, UV resistance | Outdoor, plumbing |

Silicone | Extreme temperature tolerance | High/low temperature areas |

Fluorosilicone (FKM) | Chemical resistance, high temp | Chemical plants, aerospace |

Neoprene | Flexibility | Moving parts, complex shapes |

Food-grade Silicone | Food safety compliance | Food processing |

Lixu Rubber uses advanced production methods and offers customization to meet your specific requirements. Their expertise ensures reliable sealing, durability, and compliance with industry standards.

Tip: Always balance cost and longevity. Choosing a less expensive gasket may lead to higher replacement costs over time.

You need to compare flat gaskets before making a selection for your system. The table below highlights the main differences between popular gasket materials. You can see how each material performs in temperature resistance, chemical compatibility, durability, and cost. This helps you choose the right gasket for your sealing needs.

Feature | Silicone Gasket | NBR Gasket | EPDM Gasket | FKM Gasket | Neoprene Gasket | Butyl Gasket |

|---|---|---|---|---|---|---|

Temperature Resistance | -75°F to 450°F | -30°F to 220°F | -40°F to 300°F | -20°F to 400°F | -40°F to 200°F | -40°F to 225°F |

Chemical Resistance | Excellent | Good (oils/fuels) | Good (water/steam) | Excellent (acids/fuels) | Moderate | Excellent (gases) |

Durability | High | Moderate | High | High | Moderate | High |

Cost | Higher | Lower | Moderate | Higher | Moderate | Moderate |

Silicone gaskets last longer outdoors because they resist UV rays, ozone, and weathering. NBR gaskets work well in mechanical systems with oil and fuel. EPDM gaskets handle water and steam, while FKM gaskets perform in harsh chemical environments.

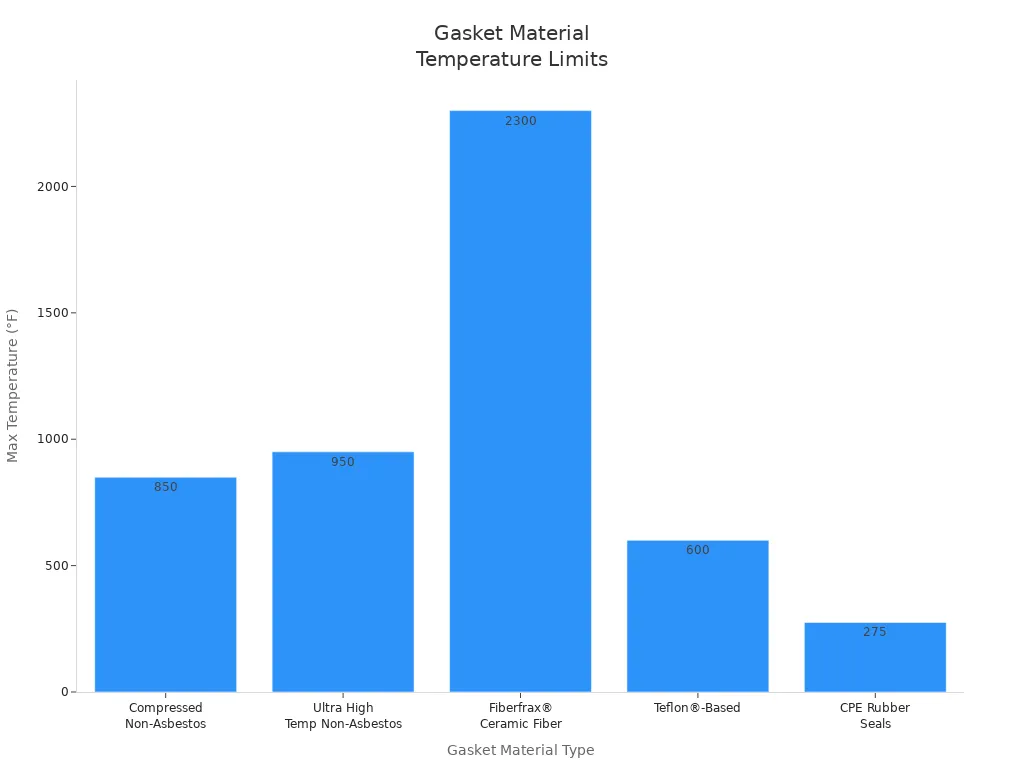

You should match the gasket material to your application for the best results. Flat gaskets come in many types, and each one fits a specific use case. The chart below shows the temperature limits for common gasket materials.

Consider these best-use scenarios for flat gaskets:

Use silicone gaskets for high-temperature and outdoor applications.

Choose NBR gaskets for automotive and machinery sealing with oil or fuel.

Select EPDM gaskets for plumbing, HVAC, and water systems.

Pick FKM gaskets for chemical processing and aerospace.

Install butyl gaskets in gas handling and vacuum chambers.

Apply neoprene gaskets for flexible sealing in moving parts.

Tip: Always check the temperature and chemical compatibility of your gasket before installation. This ensures reliable sealing and extends the life of your system.

Flat gaskets provide strong sealing and durability when you select the right material for your needs. You improve system performance and reduce maintenance by choosing the best gasket for each scenario.

You need to understand the differences between flat rubber gasket materials and types to make the best choice for your system. Each gasket offers unique properties for sealing, such as temperature resistance, chemical compatibility, and durability. Consider factors like pressure, media exposure, and industry standards before making a selection.

High-quality materials improve sealing and prevent leaks.

Reliable gaskets reduce maintenance and extend equipment life.

Matching the gasket to your application boosts efficiency.

Consult experienced suppliers like Lixu Rubber to ensure you get the right gasket for your needs. Prioritize quality, reliability, and application fit for long-term sealing performance.

Silicone and FKM gaskets handle high temperatures. Silicone works up to 450°F. FKM resists up to 400°F. You should choose these materials for ovens, engines, or chemical plants.

You need to match gasket thickness to your flange gap and pressure. Thicker gaskets seal uneven surfaces. Thinner gaskets work for smooth, flat flanges. Always check manufacturer recommendations.

Yes, you can use food-grade silicone gaskets.

EPDM gaskets resist UV, ozone, and weather. You should use EPDM for outdoor systems.