Views: 0 Author: Site Editor Publish Time: 2026-01-08 Origin: Site

You rely on a flat rubber gasket to create a tight seal between two surfaces. This essential rubber component prevents leaks, cushions impact, and reduces vibration in equipment. Many industries, such as automotive, food, and electronics, depend on rubber gaskets for consistent performance. The functions of rubber gaskets go beyond sealing—they protect machinery and extend its lifespan. Lixu Rubber provides a wide selection of rubber gaskets and seals, made from advanced rubber materials to meet your toughest requirements. You should know that improper material selection, design flaws, or installation mistakes can cause a gasket to fail. Review the table below to learn about the most common causes of failure:

Cause of Failure | Description |

|---|---|

Design Flaws | Issues like uneven stress distribution and improper groove design can lead to seal failure. |

Improper Material Selection | Choosing unsuitable rubber materials for specific conditions can cause degradation and failure. |

Manufacturing Quality Issues | Problems during production, such as poor quality control, can result in defects leading to failure. |

Usage Errors | Incorrect installation or inappropriate operating conditions can compromise seal performance. |

You see rubber flat gaskets in many machines and systems. These gaskets are thin, flat pieces made from rubber. You use them to fill the space between two surfaces. When you tighten the surfaces together, the rubber flat gaskets create a seal. This seal keeps liquids and gases from leaking out. You find rubber flat gaskets in engines, pumps, pipes, and even in household appliances. The flat shape makes them easy to install and remove. You can choose different sizes and thicknesses to fit your needs. Rubber flat gaskets come in many types of rubber, such as EPDM, NBR, silicone, and FKM. Each type has special properties. You pick the right rubber flat gaskets based on the temperature, pressure, and chemicals in your system.

Rubber flat gaskets work by creating a tight seal between two surfaces. When you press the gasket between the surfaces, the rubber compresses. This compression fills any small gaps or uneven spots. The rubber flat gaskets stop fluids and gases from escaping. You rely on rubber flat gaskets in high-pressure and high-temperature environments. The rubber material can handle changes in pressure and temperature. You use rubber flat gaskets to keep your equipment safe and leak-free.

Flat ring gaskets play a vital role in preventing leaks in industrial equipment and systems. By creating a tight seal between two surfaces, these gaskets help maintain the integrity of the system and ensure the safe and efficient operation of machinery.

You can see how rubber flat gaskets help in many ways:

They keep oil, water, and gas inside pipes and tanks.

They protect machines from damage caused by leaks.

They help your equipment run smoothly and safely.

Rubber flat gaskets also manage pressure differences. When the pressure inside a system changes, the rubber flat gaskets adjust to keep the seal tight. You do not have to worry about leaks, even when the temperature goes up or down. The rubber flat gaskets can handle thermal expansion. This means the gasket stays in place and keeps working, even in tough conditions.

Rubber flat gaskets have many unique features that make them useful in different industries. You can count on these features to solve many sealing problems.

Flexibility: Rubber flat gaskets bend and stretch to fit uneven surfaces. You get a good seal, even if the surfaces are not perfect.

Chemical Resistance: Many rubber flat gaskets resist oils, acids, and chemicals. You can use them in harsh environments without worry.

Temperature Range: Rubber flat gaskets work in both hot and cold conditions. Some types can handle temperatures from -40℃ to +260℃.

Vibration Dampening: Rubber flat gaskets absorb shocks and reduce vibration. Your machines last longer and make less noise.

Easy Customization: You can order rubber flat gaskets in many shapes and sizes. This makes it easy to find the right gasket for your job.

Here is a table that shows some key features of rubber flat gaskets:

Feature | Benefit for You |

|---|---|

Flexibility | Seals uneven surfaces |

Chemical Resistance | Works with oils and acids |

Temperature Range | Handles extreme heat and cold |

Vibration Dampening | Reduces noise and wear |

Custom Sizes | Fits your specific needs |

You use rubber flat gaskets because they are reliable and easy to install. You can trust them to keep your systems running smoothly. Rubber flat gaskets help you prevent leaks, protect your equipment, and save money on repairs.

You can choose from many types of rubber gaskets for your sealing needs. The most common types of rubber flat gaskets include EPDM, NBR (Nitrile), silicone, and FKM (Viton). Each material offers unique benefits for different environments. EPDM rubber resists sunlight, ozone, and weather, making it perfect for outdoor use. NBR rubber stands out for its oil and fuel resistance, so you often see it in automotive and machinery applications. Silicone rubber handles extreme temperatures and works well in food and medical equipment. FKM rubber provides excellent resistance to harsh chemicals and high temperatures, which makes it ideal for chemical processing and oil and gas industries.

You will also find other types of rubber gaskets, such as neoprene, chloroprene, and natural rubber. These materials add more options for your specific requirements.

Nitrile (Buna-N)

EPDM

Neoprene

Silicone

Viton

Chloroprene

Natural Rubber

PTFE (Teflon)

The key properties of each rubber material affect how well the gasket performs in your system. You need to match the types of rubber flat gaskets to your application. For example, NBR rubber gaskets resist oil and fuel, so you use them in engines and pumps. EPDM rubber gaskets handle hot water and weather, making them great for outdoor and water treatment systems. Silicone rubber gaskets offer flexibility at extreme temperatures and meet food safety standards. FKM rubber gaskets resist aggressive chemicals and high heat, which is important in chemical plants.

Material | Key Properties | Best Use Cases |

|---|---|---|

NBR | Oil & Fuel Resistance | Oil and fuel systems |

FKM | High Temp & Chemical Resistance | Chemical, oil, and gas industries |

EPDM | Weather & Hot Water Resistance | Outdoor, water treatment |

Silicone | Extreme Temp Flexibility & Food-Grade | Food, beverage, medical |

You want your rubber gaskets to last in tough conditions. The types of rubber flat gaskets from Lixu Rubber can handle harsh environments. EPDM rubber gaskets resist sunlight and heat, so you can use them outdoors. Silicone rubber gaskets work in extreme hot or cold temperatures. FKM rubber gaskets stand up to aggressive chemicals and high heat. NBR rubber gaskets perform well in oily or greasy settings.

Lixu Rubber uses advanced manufacturing techniques to make sure your gaskets meet strict standards. Automation equipment, vulcanization robots, and optical inspection machines help create high-quality rubber gaskets. You can also request custom shapes and sizes. Lixu Rubber offers bespoke designs and industry compliance options to fit your needs.

Customization Option | Description |

|---|---|

Bespoke Designs | Tailored designs based on your drawings for unique applications. |

Industry Compliance Standards | Options available to meet various industry certifications. |

Tip: Always select the right types of rubber flat gaskets for your environment. This ensures long-lasting performance and safety.

You see rubber gaskets in many automotive and machinery applications. These flat rubber gaskets create reliable seals between engine parts, exhaust systems, and transmission components. You use rubber gaskets to prevent leakage of oil, coolant, and gases. In engines, rubber gaskets seal cylinder heads, valve covers, and intake manifolds. You rely on high-temperature resistant rubber gaskets, such as silicone or FKM, for exhaust systems. These gaskets stop leakage and withstand extreme heat. You also use rubber gaskets to absorb vibration and shock, which protects internal components and reduces noise.

Application Area | Description |

|---|---|

Engine Sealing | Used in cylinder heads, valve covers, and intake manifolds to prevent oil and coolant leaks. |

Exhaust Systems | High-temperature resistant gaskets, such as silicone or Viton, provide reliable seals in exhaust systems. |

Rubber gaskets help you stop leakage between connected parts in the automotive industry.

You depend on rubber gaskets for durability and temperature resistance in machinery.

You use rubber gaskets in chemical plants and industrial equipment to create leak-proof connections. These flat rubber gaskets seal joints in pipes, pumps, and tanks. You rely on rubber gaskets for preventing leakage of fluids, gases, and contaminants. Rubber gaskets also insulate equipment, minimize heat transfer, and reduce noise. You benefit from rubber gaskets that absorb vibration and shock, which extends the lifespan of your machinery. In industrial systems, rubber gaskets maintain pressure and improve performance by reducing friction and energy loss.

Function | Description |

|---|---|

Sealing | Creates a tight barrier to prevent leakage of fluids, gases, or contaminants, ensuring system integrity. |

Insulation | Acts as a protective layer to minimize heat transfer, electrical conductivity, and noise transmission. |

Vibration Damping | Absorbs vibrations to reduce wear and prolong equipment lifespan. |

Leak Prevention | Stops unwanted escape or entry of fluids or gases, crucial for safety and environmental protection. |

Pressure Maintenance | Effectively seals joints to maintain specific pressure levels in industrial systems. |

Performance Improvement | Reduces friction and energy losses, enhancing efficiency and extending equipment lifespan. |

You find rubber gaskets in food processing, medical devices, and electronics manufacturing. These flat rubber gaskets seal equipment to prevent leakage and contamination. In food processing, rubber gaskets protect raw meat and poultry from cross-contamination. Beverage bottlers use rubber gaskets to prevent leaks when filling bottles. You rely on silicone rubber gaskets for their cleanliness and ability to handle thermal fluctuations. In medical devices, rubber gaskets provide electrical insulation and seal sensitive components. Electronics manufacturers use rubber gaskets to seal enclosures and protect against dust and moisture.

You use rubber gaskets in aerospace, automotive, chemical processing, construction, electronics, food and beverage, marine, oil and gas, pharmaceutical, and power generation applications.

Silicone rubber gaskets are essential for sealing components in medical devices, food systems, and electronic enclosures.

Lixu Rubber offers expertise in designing rubber gaskets for these common applications. You can trust their products to provide leak-proof connections, absorb vibration and shock, and maintain system integrity in demanding environments.

When you look at the advantages of rubber flat gaskets, durability stands out. These gaskets can handle mechanical stress and temperature changes for long periods. You benefit from their robust construction, which helps maintain a reliable seal even in tough conditions. The abrasion resistance and elasticity of rubber allow these gaskets to endure many cycles of compression and recovery. This means you can use them in systems that open and close often without worrying about quick wear.

Rubber flat gaskets withstand mechanical stress and temperature swings.

Their strong build and resistance to wear help you keep a tight seal.

The elasticity of rubber lets the gasket recover its shape after each use.

Flexibility is another key advantage. The flexibility of rubber flat gaskets lets them conform to the surfaces they seal. You get a tight fit, even on surfaces that are not perfectly smooth. This feature is especially important in dynamic mechanical systems. The gasket keeps its seal and performance, even when the surfaces move or shift.

You will notice that the advantages of rubber flat gaskets include:

Long-lasting performance in demanding environments

Ability to handle repeated use without losing shape

Flexibility to seal uneven or moving surfaces

These qualities make rubber flat gaskets a top choice for many industries.

You need gaskets that can resist chemicals and temperature extremes. The advantages of rubber flat gaskets include their ability to handle a wide range of chemicals. Different rubber materials offer different levels of resistance. For example, neoprene and nitrile gaskets provide good protection against oils, solvents, and some chemicals.

Material | Chemical Resistance Ratings |

|---|---|

Neoprene | Excellent resistance to petroleum-based concoctions, greases, solvents, methyl and ethyl alcohols, certain salt mixtures, and some alkaline solutions |

Nitrile | Good level of all-round resistance to oils and chemicals |

Temperature resistance is another important factor. You want your gasket to work well in both hot and cold environments. The table below shows the temperature ranges for common rubber gasket materials:

Gasket Material | Temperature Range |

|---|---|

Tuf-Flex®/Ansi-Flex | -20ºF to 300ºF (-29ºC to 149ºC) |

EPDM (peroxide cured) | -30ºF to 300ºF (-34ºC to 149ºC) |

Buna | -30ºF to 200ºF (-34ºC to 93ºC) |

You can see that the advantages of rubber flat gaskets include their ability to work in extreme temperatures. EPDM gaskets, for example, resist UV rays, ozone, and harsh weather. This makes them perfect for outdoor use. Their flexibility at low temperatures also helps you get a tight seal in cold conditions.

Benefit | Description |

|---|---|

Weather resistance | EPDM gaskets are resistant to UV rays, ozone, and extreme temperatures, making them suitable for harsh outdoor environments. |

Cost-effectiveness | Their durability and wear resistance lead to long-lasting performance, reducing the need for frequent replacements. |

Flexibility | EPDM gaskets maintain flexibility even at low temperatures, allowing them to conform to surfaces for a tight seal. |

You can rely on rubber flat gaskets to protect your equipment from chemical damage and temperature changes. This helps you keep your systems safe and efficient.

Choosing the right rubber gasket for your application is important. You should consider the environment, the type of fluid or gas, the temperature, and the pressure. The advantages of rubber flat gaskets become clear when you match the material to your needs. For example, use EPDM for outdoor or water systems, nitrile for oil and fuel, and silicone for food or medical equipment.

Tip: Always check the chemical compatibility and temperature range of the rubber material before making your choice.

When you install a rubber gasket, you need to follow best practices to avoid failure. Many gasket failures happen because of installation mistakes. The most common errors include:

Wrong gasket selection

The mounting surface is not clean

Failure to tighten to the correct torque

Reuse of old gaskets

Inappropriate gasket size

Misaligned gaskets

Selecting inappropriate thickness

Lack of lubrication

Temperature and pressure exceed the rated value

Neglecting preventive maintenance

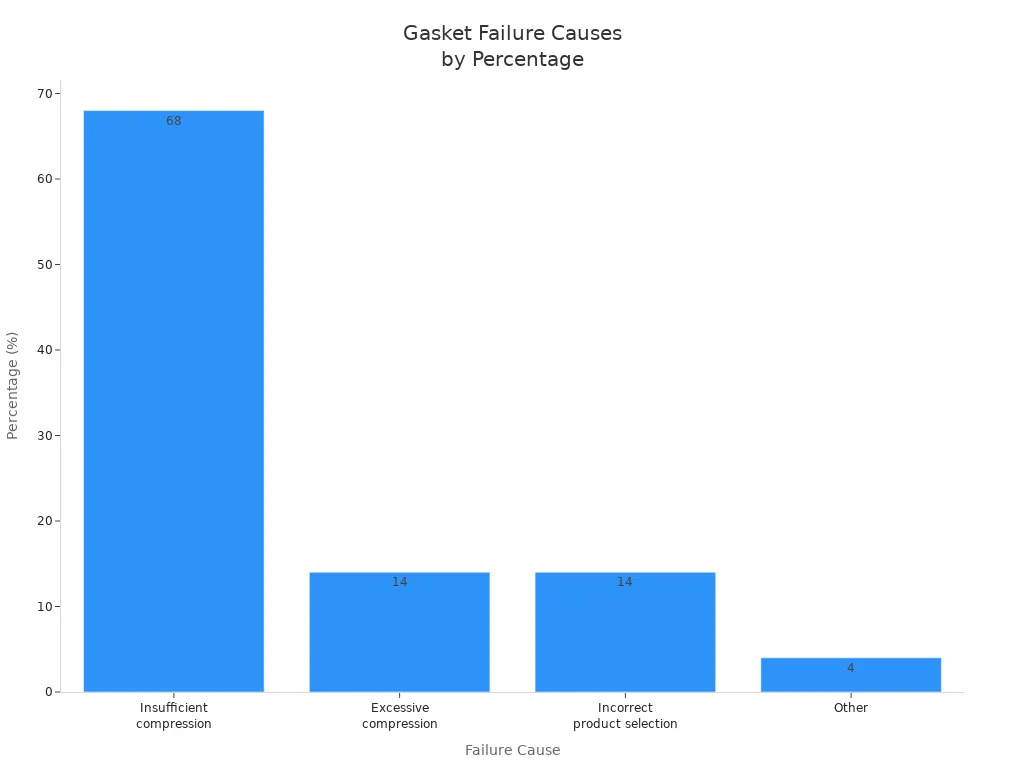

You can see from the chart below that most gasket failures come from improper compression, not from the material itself:

Cause of Gasket Failure | Percentage |

|---|---|

Insufficient compression | 68% |

Excessive compression | 14% |

Incorrect product selection | 14% |

Other | 4% |

To get the most out of the advantages of rubber flat gaskets, follow these steps:

Clean the mounting surfaces before installation.

Use the correct size and thickness for your application.

Tighten bolts to the recommended torque.

Do not reuse old gaskets.

Check that the temperature and pressure do not exceed the gasket’s rating.

Perform regular maintenance checks.

By following these tips, you can ensure a reliable seal and long-lasting performance. The advantages of rubber flat gaskets, such as durability, flexibility, and resistance to harsh environments, help you maintain system integrity and prevent leaks. When you focus on maintaining pressure and proper installation, you reduce downtime and save on repair costs.

If you need help choosing the right rubber gasket, consult with experts or trusted manufacturers. Lixu Rubber offers a wide range of options and can help you find the best solution for your needs. Remember, maintaining pressure and selecting the right material are key to a successful seal.

You have learned that flat rubber gaskets offer reliable sealing, flexibility, and resistance to harsh environments. You can use them in many industries because they adapt to different surfaces and conditions. When you choose a gasket, consider material selection, design, and quality control. Regular inspection and proper installation help you avoid leaks and extend gasket life. Lixu Rubber provides custom solutions and strong customer support. For the best results, consult with experts who understand your needs and can guide you through:

Picking the right material for your environment

Understanding manufacturing challenges for complex designs

Ensuring strict quality checks for durability

Receiving clear communication and support

You use a flat rubber gasket to create a tight seal between two surfaces. This seal prevents leaks, reduces vibration, and protects equipment from damage.

You should match the material to your environment. For example:

You should not reuse a flat rubber gasket. Reusing it can cause leaks or seal failure. Always use a new gasket for the best performance.

You need to clean both surfaces first. Place the gasket evenly, then tighten bolts to the recommended torque. Do not overtighten. Check for proper alignment.

Yes! You can request custom shapes and sizes from Lixu Rubber. Just provide your specifications or drawings, and they will manufacture a gasket to fit your needs.