Views: 0 Author: Site Editor Publish Time: 2025-09-12 Origin: Site

An NBR O RING, also known as nitrile, buna-n, or acrylonitrile butadiene rubber, serves as a reliable seal in a wide range of machines and systems. The table below shows the common names for NBR O RING:

| Common Names | Trade Names |

|---|---|

| Buna-N | Nipol® |

| Nitrile | |

| NBR | |

| Acrylonitrile Butadiene Rubber |

NBR O RING is highly resistant to oil, fuel, and physical damage, making it an excellent option for various applications. NBR O RING is widely used in automotive, aerospace, heavy machinery, and oil & gas industries. These O-Rings perform effectively in engines, fuel systems, and other types of equipment.

NBR O-Rings are made from nitrile butadiene rubber. This material resists oil and fuel. That makes them great for cars and factories.

These O-Rings have different hardness levels. This lets them work in many places. They can be soft for medical tools. They can also be strong for hydraulic systems.

NBR O-Rings can last five to ten years. How long they last depends on how they are used. They help stop leaks in engines, fuel systems, and machines.

Engineers like NBR O-Rings because they are not expensive. They also last a long time. They work well under pressure and in very hot or cold places.

NBR O-Rings work best with oils and fuels. They should not be used with acetone, benzene, or steam. These things can harm them.

NBR means nitrile butadiene rubber. People make NBR by mixing acrylonitrile and butadiene. They use a process called polymerization. NBR stands up well to oils and fuels. If you add more acrylonitrile, NBR resists chemicals better. Butadiene helps NBR stay flexible and work in cold places.

NBR is made from acrylonitrile and butadiene by polymerization.

More acrylonitrile makes NBR resist oil and fuel better.

Butadiene gives NBR flexibility and helps it work in the cold.

NBR can stretch and bounce back, so it seals well and stops leaks.

NBR’s structure makes it great for sealing jobs. Mixing butadiene and acrylonitrile creates a material that resists many oils and fuels. This is important for machines that touch these liquids. The amount of acrylonitrile changes how well NBR resists chemicals. More acrylonitrile means better oil resistance, but less flexibility in the cold.

An NBR O-Ring is a round seal made from nitrile butadiene rubber. Engineers use NBR O-Rings to stop leaks in machines. These rings fit into grooves and get squeezed between two parts. This makes a tight seal against liquids and gases.

NBR O-Rings come in different hardness levels for different jobs. The table below shows the hardness ratings and where they are used:

| Shore A Hardness | Description and Applications |

|---|---|

| 50 - 60 | Very soft and bendy, used in medical tools like syringes and catheters for a gentle seal. |

| 70 - 80 | Most common, balances softness and strength, found in cars and home machines like washing machines. |

| 80 - 90 | Good for high pressure, used in hydraulic systems and big machines. |

NBR O-Rings are also strong. For example, a 70 durometer NBR O-Ring can stretch up to 250%. Many good NBR types can stretch even more. The table below compares NBR O-Rings and FKM O-Rings for strength and stretch:

| Property | NBR O-Rings | FKM O-Rings |

|---|---|---|

| Tensile Strength | 15-25 MPa | 20-35 MPa |

| Elongation at Break | 300-500% | 200-400% |

NBR O-Rings work in many temperatures. They can run all the time up to 120°C (248°F) and handle short bursts up to 135°C (275°F).

| Property | Value |

|---|---|

| Maximum Continuous Temperature | +120°C (248°F) |

| Maximum Intermittent Spike | +135°C (275°F) |

NBR O-Rings seal well and work in many places. They resist oil, fuel, and wear, so people use them in cars, hydraulic systems, and factories. Engineers pick NBR O-Rings because they work well and do not cost too much.

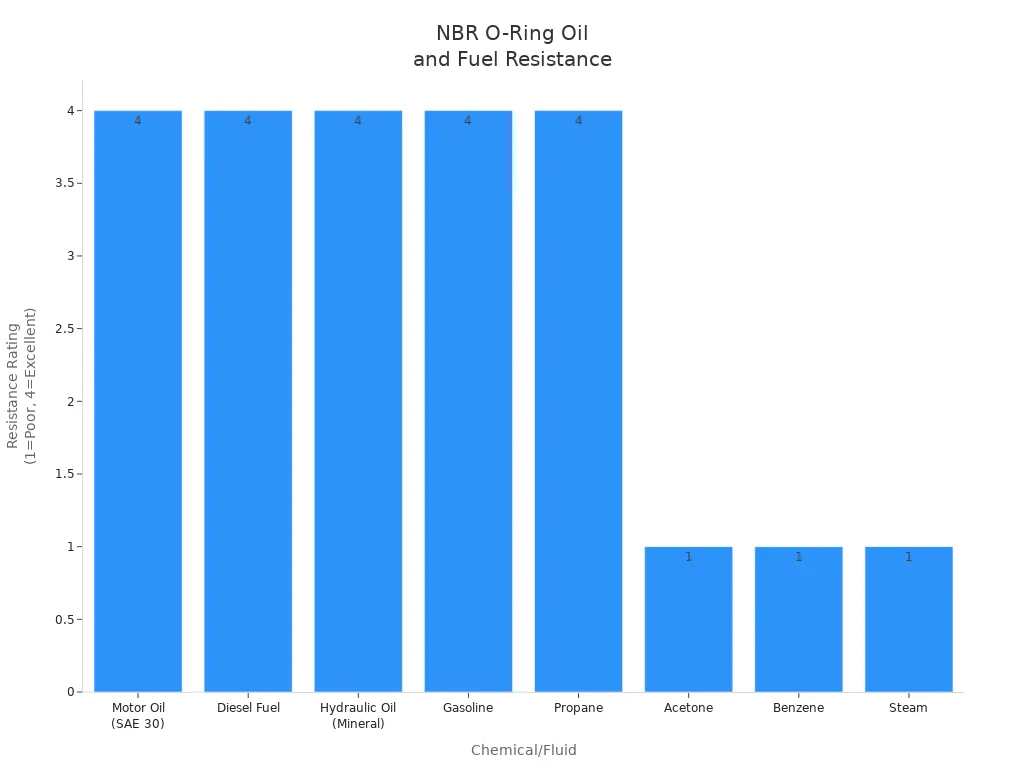

NBR is very good at resisting oils and fuels. Many companies use NBR O-Rings with motor oil, diesel, hydraulic oil, gasoline, and propane. NBR keeps its shape and seals well, even in these liquids. The table below shows how NBR works with different chemicals and fluids:

| Chemical/Fluid | Concentration | Temperature | Rating | Notes |

|---|---|---|---|---|

| Motor Oil (SAE 30) | 100% | 120°C | Excellent | Great for cars |

| Diesel Fuel | 100% | Room Temp | Excellent | Good for fuel systems |

| Hydraulic Oil (Mineral) | 100% | 80°C | Excellent | Used in many machines |

| Gasoline | 100% | Room Temp | Excellent | Used in car fuel systems |

| Propane | 100% | Room Temp | Excellent | Used in LPG systems |

| Acetone | 100% | Room Temp | Poor | Makes NBR swell a lot |

| Benzene | 100% | Room Temp | Poor | FKM is better for this |

| Steam | 100% | Above 100°C | Poor | EPDM works better for steam |

NBR O-Rings work great with most oils and fuels, but not with acetone, benzene, or steam.

How well NBR resists oil depends on acrylonitrile. More acrylonitrile means better oil resistance, but less bendy in the cold. Medium levels are good for most uses.

NBR O-Rings are also strong and tough. They do not wear out fast and can last for years. Most NBR seals work well for five to ten years. Many hydraulic systems use NBR because it handles pressure and seals tight. The table below compares NBR with other materials:

| Material | Oil Resistance | Temperature Resistance |

|---|---|---|

| NBR | Good | Up to 120°C |

| FKM | Excellent | Up to 300°C |

NBR O-Rings do not break easily from stretching or rubbing. They can fail from being squeezed too much, pushed out, or worn down. Picking the right material and installing it right helps stop these problems.

NBR O-Rings last long and keep sealing.

They are best for normal hydraulic and fuel systems.

They can last up to ten years if used right.

Cars and trucks use NBR O-Rings for many jobs. Engineers pick NBR O-Rings because they resist oils and fuels well. These rings stop leaks in engines, gearboxes, fuel systems, brakes, and air conditioning. NBR O-Rings work great with oil, so they are used a lot in vehicles. They help keep cars running without leaks.

Airplanes also use NBR O-Rings in their fuel systems. Planes need good seals to stay safe and avoid leaks. NBR O-Rings seal well even in tough places. Car makers like NBR because it lasts long and does not cost too much. Many new and old cars use NBR O-Rings for repairs and new parts.

Tip: NBR O-Rings help engines last longer by stopping oil and fuel leaks.

Hydraulic and pneumatic machines need strong seals. NBR O-Rings work well because they resist oil and do not wear out fast. Pumps, compressors, and other machines use NBR O-Rings to seal tight. These rings keep their shape and strength under pressure. This helps stop leaks.

The table below shows how NBR O-Rings compare to FKM and EPDM O-Rings:

| O-Ring Type | Key Properties | Best Applications |

|---|---|---|

| NBR | Oil resistance, cost-effective | Hydraulic systems, automotive |

| FKM (Viton) | Excellent chemical and heat resistance | Extreme conditions |

| EPDM | Water and steam resistance | Not suitable for oil applications |

NBR O-Rings are good with oils and seal well in hydraulic systems. FKM O-Rings are better for high heat or strong chemicals. EPDM O-Rings work best with water and steam, but not oil. Engineers often choose NBR for machines because it works well and is not expensive.

Many factories use NBR O-Rings to seal and protect machines. These rings are found in chemical plants, food machines, medicine equipment, electronics, and water systems. NBR O-Rings resist oil and fuel, so they are great for many machines.

The table below lists why engineers use NBR O-Rings in factories:

| Property/Advantage | Description |

|---|---|

| Resistance to petroleum-based oils and fuels | Excellent compatibility with oils and fuels, making it ideal for various applications. |

| Cost-effectiveness | NBR is one of the most economical elastomers available. |

| Versatility | Suitable for automotive, water treatment, military, and more. |

| Low compression set | Maintains shape and sealing capability over time. |

| High tensile strength | Provides durability and resistance to wear. |

| High abrasion resistance | Withstands wear and tear in demanding environments. |

| Low gas permeability | Effective sealing against gas leaks. |

NBR O-Rings are used in military and airplane machines where safety is important. They also protect batteries, sensors, and wires in electronics. Water plants use NBR O-Rings in pipes and valves to stop leaks. Food and medicine companies trust NBR O-Rings because they are safe and keep products clean.

Here are some common places where NBR O-Rings are used:

Automotive: Engines, gearboxes, fuel systems, brakes, air conditioning.

Chemical: Pipes and machines in chemical plants.

Food: Pipes and filling machines.

Medicine: Sealing and protecting equipment.

Electronics: Batteries, wires, sensors.

Water treatment: Pipes and valves.

NBR O-Rings seal well and last long in many jobs. They are useful and not expensive, so many industries use them.

NBR O-Rings are important in engines and fuel systems. Engineers put these seals in oil passages and fuel lines. They also use them in coolant systems. NBR resists oil and fuel, so engines work well. Mechanics use NBR O-Rings in fuel injectors and pumps. They also put them in carburetors. These rings stop leaks and protect engine parts.

The table below explains why NBR O-Rings are good for fuel lines:

| Key Factor | Description |

|---|---|

| Excellent Oil Resistance | Stays strong against oils and fuels, great for fuel lines. |

| Good Compression Set Resistance | Keeps its shape after being squeezed, so it seals well. |

| Broad Temperature Range | Works from -40°C to 120°C, good for hot and cold places. |

| Cost-Effectiveness | Not expensive, so you can replace them often. |

| Versatility | Used in many jobs and industries. |

| Excellent Sealing Performance | Seals tightly, stops leaks of fluids and gases. |

| Easy Installation | Simple to put in, saves time. |

| Compatibility with Common Fluids | Works with water, oil, gasoline, and hydraulic fluids. |

NBR O-Rings save money for car repairs. Car owners and mechanics like NBR because it lasts long. It fits many engines. These seals help stop oil and fuel leaks. This keeps cars safe and working well.

Tip: NBR O-Rings are simple to install and change. They are a smart pick for regular fuel system maintenance.

Machines in factories and workshops use NBR O-Rings for sealing. These rings are found in hydraulic cylinders and pumps. They are also in compressors and mechanical seals. NBR handles high pressure and tough jobs. It helps machines run without leaks or breakdowns.

The table below shows how NBR O-Rings help machines work better:

| Aspect | Contribution to Reliability |

|---|---|

| Material Composition | Made from acrylonitrile and butadiene, so it is flexible and strong. |

| Temperature Stability | Works well in very hot or cold places. |

| Chemical Resistance | Stays strong against many chemicals, so it lasts longer. |

| Mechanical Durability | Strong material lets it seal well under pressure. |

| Advanced Manufacturing | New ways to make NBR O-Rings help them last longer. |

| Surface Treatments | Coatings like PTFE and silicone help them work better and last longer. |

NBR O-Rings work in many places. They are used in cars, airplanes, and hydraulic systems. These rings slide easily and do not need much care. New sealing technology makes NBR O-Rings better than old seals.

NBR O-Rings are cheap and work in oil and fuel jobs.

Silicone O-Rings are better for very hot places but cost more.

Fluorocarbon O-Rings resist chemicals well but are expensive.

NBR O-Rings are the best choice for most jobs.

NBR O-Rings help machines last longer and cost less to fix. They are used in oil passages, coolant systems, and mechanical seals. This shows why many industries use them.

NBR O-Rings are useful and not expensive. They work well for sealing in many jobs. People like them because they have many good features:

They resist oils and fuels very well.

They are strong and do not wear out fast.

They do not tear or lose their shape easily.

They work with many oils, chemicals, and fluids.

They cost less than other types of elastomers.

NBR O-Rings last a long time and need fewer changes. This helps save money on repairs. They are tough and work well in cars, oil, and gas jobs. As new machines are made, companies keep making NBR O-Rings better. They want them to work even longer and be safer for the planet.

| Aspect | Details |

|---|---|

| Non-biodegradability | NBR O-Rings do not break down fast. They can stay in nature for many years. |

| Environmental Implications | Old O-Rings can fill up landfills. They may harm animals and plants. |

| Recycling Challenges | Recycling is hard because of how they are made. Some places can recycle rubber, but not all can. |

NBR O-Rings seal oil, fuel, and machine parts well. Engineers pick them because they are strong, useful, and a good deal.

NBR O-Rings work well in many systems because they resist oil and fuel. They keep engines, pumps, and machines running without leaks. Many industries use these O-Rings in their systems to protect parts and improve safety.

Yes, NBR O-Rings are a top choice for hydraulic systems. They seal moving parts and stop leaks. These O-Rings handle pressure changes and keep hydraulic systems working smoothly in many machines.

NBR O-Rings resist gasoline and diesel. They seal fuel lines and pumps in many systems. These O-Rings help prevent leaks and keep fuel systems safe. Mechanics trust them for repairs and new parts.

NBR O-Rings work in water systems, but they perform best with oil and fuel. Some water systems use them for sealing pipes and valves. For hot water or steam, other materials may work better.

NBR O-Rings can last five to ten years in most systems. Their lifespan depends on temperature, pressure, and the type of fluid in the systems. Regular checks help keep systems safe and working well.